ATC MULTI-TECHNIQUE&HYBRID SYSTEMS | AJA International ATC-M Series Multi-Technique Systems are versatile tools that combine various thin film deposition,ion milling and analytical operations in a single chamber(Hybrid Systems)or in multiple chambers(Multi-Chamber Systems)to allow the in-situ transfer of substrates from process to process without breaking vacuum.

These systems can be built in HV or UHV configurations,and in either cylindrical,box or machined chambers styles.

Multi-Techniques employed include:

|

| | - Magnetron Sputtering

- E-Beam Evaporation

- Thermal Evaporation

- Ion Milling

- Ion Beam Deposition

- Pulsed Laser Deposition

- Ellipsometry

- Rapid Thermal Anneal

- Oxygenation and Nitridization

- XPS/AUGER/LEED Analysis

- MBE

- RHEED

- MOS

- SIMS

- RIBE

|

TYPICAL MULTI-TECHNIQUE SYSTEM CONFIGURATIONSDual ATC-Orion UHV with Common Load-Lock | Dual ATC-ORION UHV with Common Load-Lock

System features both sputter and evaporation process chambers with(8)A320-O 2" UHV sputter sources, (1) 6-pocket 15cc UHV linear e-gun, (4) Resistive Thermal Sources, 850°C rotating

substrate heaters with RF bias, secondary tilting/cooled stage, RHEED, computer control, load-lock cassette with in-situ mask exchange for 4"diameter substrates and chamber to chamber

transfer system. |

| ATC UHV Dual Chambers

Dual UHV ATC 1800/2200E(Sputter/E-Beam)system with(4) A320-XP 2" UHV sputter sources with in-situ tilt, (2) 4-pocket 15cc UHV linear e-guns, RF ion source, 1200 l/s turbopumps,

850°C rotating substrate heaters with RF bias, computer control, and common vertex load-lock for 100 mm Ø substrates.

|

ATC Dual Chamber with Common Cassette Load-lock

| ATC Dual UHV

The dual sputtering system above is connected by a common load-lock with(6)position cassette with"vacuum suitcase"compatibility. The chamber on the left includes(7)fixed angle sputter

sources and has a 1.0 x 10-8 Torr base pressure. The chamber on the right features an integral bake jacket,(4)in-situ tilt sputter sources,a gridded ion source and has a base pressure in the 10-10

Torr range.

|

ATC Dual Chamber-Sputtering/Pulsed Laser Deposition | ATC Dual Sputter/PLD

The chamber on the right is a full featured ATC 2200 with(6)UHV sputter sources with in-situ tilt and an 850°C substrate heater with RF bias,Z motion and azimuthal rotation. The chamber on the left backs up to a laser via the safety tunnel and features PLD from a six target turret. This chamber also includes 850°C heating and high pressure,double differentially pumped RHEED. Both are connected by a common vertex load-lock.

|

| PLD(6)x 1" dia. Target Turret with isolation shield

|

PLD (6) x 1"Target Turret in operation

During laser operation individual targets rotate azimuthally and execute an accel/decel

wobble motion to allow uniform target erosion. |

TYPICAL HYBRID SYSTEMS CONFIGURATIONS

ATC-MC-HY with UHV Transfer Tube&Glovebox Interface | ATC-MC-HY Multi-Chamber Hybrid Deposition Tool with UHV Transfer Tube&Glovebox Interface

The ATC-HY Multi-Chamber Hybrid Deposition Tool combines two Hybrid Process Chambers,each featuring e-beam and thermal evaporation,confocal magnetron sputtering,ion beam etching with a 360 degree tilt,and a water-cooled substrate holder. In addition,a third process chamber features post anneal,oxygenation and ashing capability. All are connected via a UHV magnetic transfer tube with sectional isolation,integral load-lock and glovebox compatibility.

|

|

|

ATC 1800-HY Hybrid System

Incorporates confocal sputtering, a (6) pocket linear e-beam source, ion milling and a retractable sputter source for short working distance direct sputtering (e.g. Nb superconductors). This UHV tool also incorporates a +/- 200° tilting substrate holder with substrate cooling and azimuthal rotation.

|

|

|

ATC 2030-HY

The HV box chamber features a turbo-pumped vacuum load-lock for substrates up to 6" diameter

and Labview based computer control system which handles all sputtering and heater functions

and interfaces seamlessly with the Inficon Deposition Controller for e-beam operations.

|

ATC 2030-HY

Featuring a (6) pocket, 15cc rotary pocket electron beam source with shielding, (1) 2" and

(2) 3"magnetron sputter sources with tilt and an 850°C substrate heater with azimuthal

rotation, Z motion and RF bias.

|

|

|

ATC Orion 8-E-HY

This powerful tool features a linear UHV e-beam source, a 3" UHV sputter source with in-situ tilt, several different substrate carriers and a vacuum load lock.

|

|

|

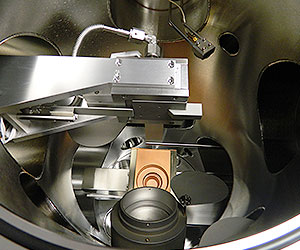

ATC Orion 8-E-HY

This view shows a tilting, water cooled ring which can accept a substrate carrier from and 850°C

lamp heater. The ring can be oriented for normal deposition from both sources or for shadow

evaporation.

|

ATC Orion 8-E-HY

The water cooled ring at the left can be replaced by a 2" 1000°C, tilting, substrate heater

with a programmable, water cooled wedge shutter for gradient film deposition.

|

|

|

ATC 1800-HY

Featuring a (6) pocket linear UHV e-beam source, a +/- 200° tilting substrate holder with

azimuthal rotation and RF bias, (2) UHV sputter sources and a 4cm, gridded ion source.

|

ATC 1800-HY

This view shows AJA's unique "magnetic bayonet" transfer system.

|

|